The difference

Preventio's Predictive Maintenance harnesses the power of AI to transform maintenance strategies in water, heating, and industrial sectors, proactively addressing challenges to save resources and costs.

Traditional Maintenance Challenges:

Frequent Downtimes

Regular maintenance often requires planned shutdowns, causing operational interruptions.

Reactive Approach

Traditional methods tend to be reactive, dealing with issues only after they have occurred, leading to unexpected breakdowns.

Inconsistent Maintenance Quality

Manual maintenance can vary in quality, potentially missing critical issues.

High Operational Costs

Regular maintenance incurs significant labor and material costs, especially if issues are detected late.

Lack of Data-Driven Decisions

Traditional maintenance often lacks real-time data analysis, leading to less informed decisions.

How Preventio Improves Maintenance:

Minimized Downtimes

Predictive maintenance identifies potential issues before they escalate, reducing the need for frequent shutdowns and maintenance-related disruptions.

Proactive Maintenance Strategy

By predicting issues before they happen, Preventio's solution allows for a more proactive approach, avoiding costly emergency repairs and reducing the risk of sudden breakdowns.

Consistent and Accurate Maintenance

AI-driven analysis ensures high-quality, consistent maintenance outcomes, reducing the likelihood of overlooking critical issues.

Cost-Effective Operations

Early detection and maintenance optimization lead to significant cost savings by reducing the frequency of extensive repairs and extending the lifespan of equipment.

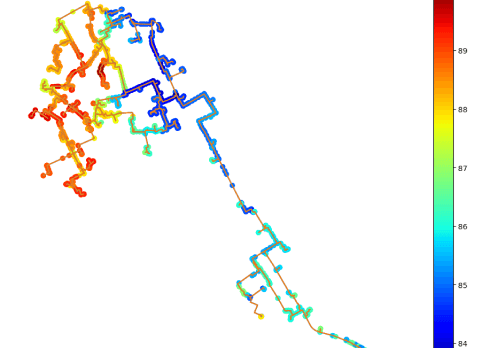

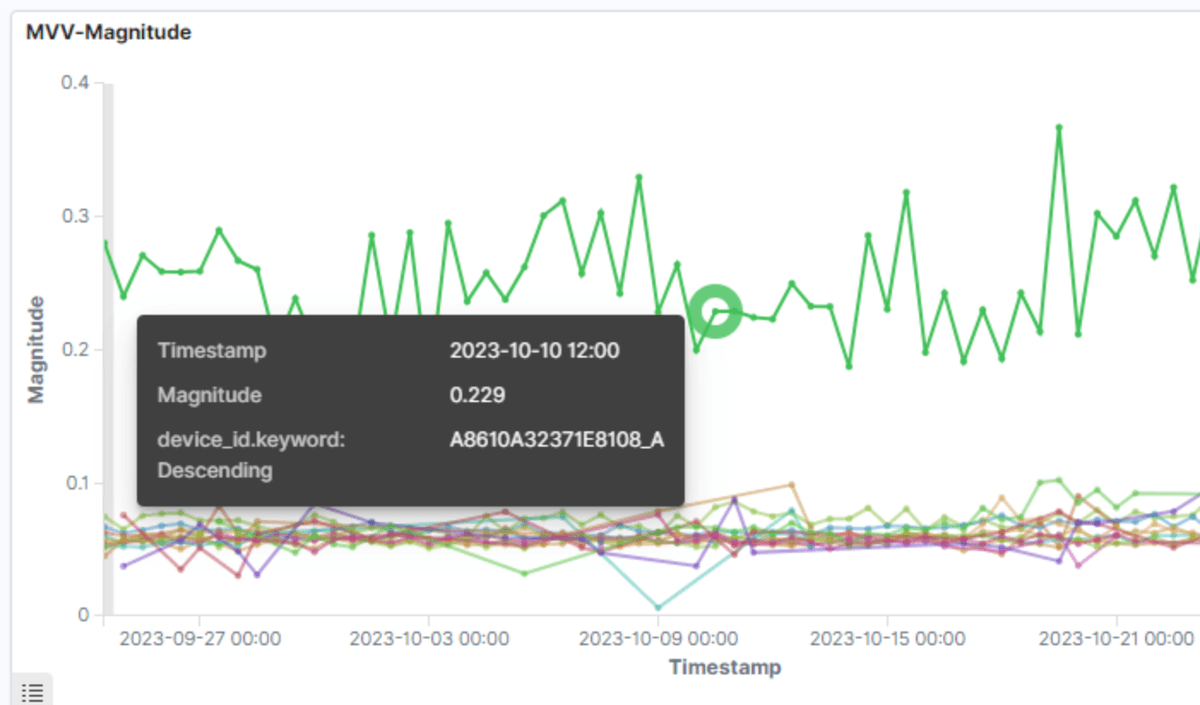

Data-Driven Insights

Leveraging real-time data and advanced analytics, Preventio's tool enables smarter, more informed maintenance decisions, enhancing overall operational efficiency.

How it works

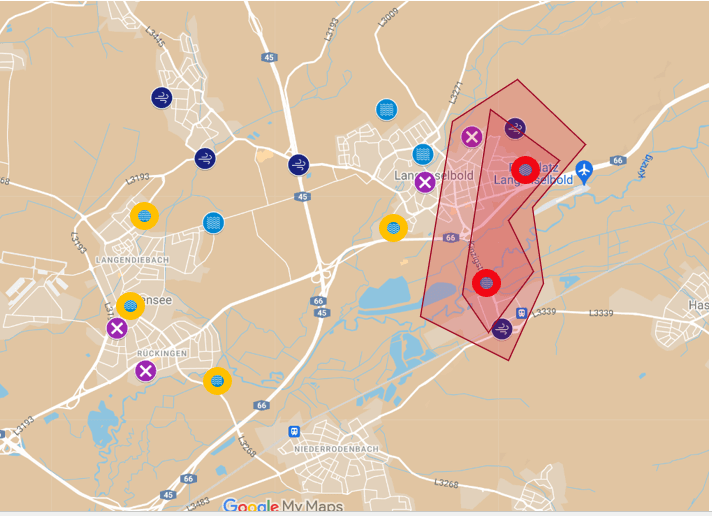

Monitoring

Continuously tracking system performance to identify potential issues early.

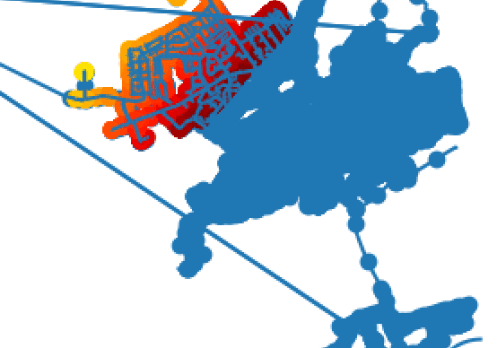

Advanced Predictive Analysis

Using AI to forecast maintenance needs, preventing costly breakdowns.

Resource Optimization

Efficiently managing resources to reduce waste and environmental impact

Advanced Predictive Analysis

Strategically planning maintenance activities to avoid disruptions

Benefits

Minimized Downtime

Reducing unplanned outages and maintaining operational stability.

Cost Savings

Lowering maintenance costs and preventing expensive repairs.

Enhanced Efficiency

Improving overall operational efficiency and resource utilization.

Environmental Sustainability

Contributing to sustainability by minimizing resource wastage.

What our customers say

Want to give it a try?

Get in Touch

Discover how our advanced AI-driven technology at Preventio can help reduce downtime, enhance efficiency and save resources.

Transform your Business with AI

Discover How Our Expertise Can Elevate Your Business - Explore Our Case Study Now!